Rimage Perfect Print

- Index Mark

- Artwork Placement

- Full Design Specification (pdf file)

Artwork Placement

During the silk screened process, each color is applied separately and the surface of the disc could have a ridge or step at the edge of a color.

The surface of a disc will have steps at the object boundaries if:

- screened with spot color objects

- a spot color object is screened over another

- where spot color coating thickness is unequal

These steps can prevent the printhead from developing sufficient pressure over print areas on the underlying inks.

Some disc surfaces are too rough for successful thermal printing. These surfaces include ink-jet printable, process colored, or textured silk screen disc surfaces. Disc surfaces that are inherently smooth enough for successful thermal printing are spin coated lacquer (blank discs); silk-screened single ink (major manufacturer’s matte gold, white, or silver thermally printable discs); and offset printed discs.

Placement of the artwork (silk-screen ink) is important so the thermal ink from the printer can be adhered to the disc. The type of screening may not allow the thermal from the printer to adhere to the disc.

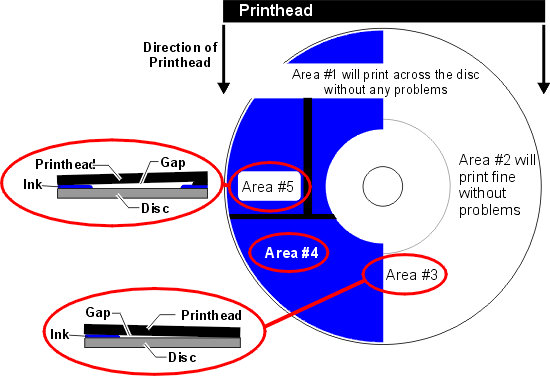

- Area #1 – provides the easiest way to ensure sufficient print pressure by having an open horizontal band spanning the entire width of the disk without any silk-screened objects, as in Area #1, then print directly to the surface of the disc.”

- Area #2 – is far enough away from the silk-screened ink so the printhead and ribbon contact the surface of the media. Adequate horizontal margin between screened objects and over-print is required. 3mm works in most cases.

- Area #3 – may have problems since the blue ink may lift the printhead away from direct contact of the disc. See the side illustration for a cross-sectional diagram.

- Area #4 – will print well if the blue ink allows the thermal based ink to adhere to it. Most silk-screened inks do not allow the thermal ink to adhere to it. The blue ink must also be a solid ink, not a dithered pattern where two colors are spot processed on the disc. You can call Rimage Sales for companies that have experience with Rimage silk-screen requirements that adheres thermally based ink from the Rimage printer.

- Area #5 – The blue ink adds some thickness and the black ink adds another layer of thickness. See the diagram to the left of Area #5. These steps of ink thickness can prevent the printhead from providing sufficient pressure over the print areas on the underlying surface.