Rimage Perfect Print

Index Marking

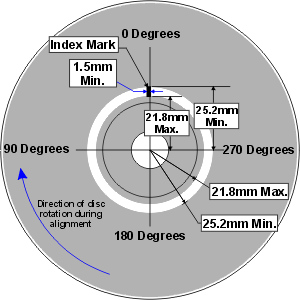

A single black, or cyan colored index mark is to be silkscreened on the disc with a specified relation to the pre-printed image.

Perfect Print Alignment

When Perfect Print is enabled in the Production Server software, the system will use the Index Mark Angle parameter to align the disc with the printer prior to printing. The screened and printed images will be aligned to within system tolerances. Perfect Print adds about 6 seconds to the print time for each disc when using Producer II transporters.

The leading edge of the index mark may be placed at any angle (in steps of 0.25) in the artwork. A user parameter (Index Mark Angle) in the Production Server software tells the system the angle of the index mark Perfect Print process does not create absolute alignment from CD to CD. Silk screen printing systems typically can hold an image to disk registration accuracy of 0.1mm (0.004″).

Positioning Accuracy is as follows:

- Angular 1°

- Horizontal (X) 0.75mm (0.03″)

- Vertical (Y) 0.25mm (0.01″)

The index ring begins at a radius of 21.8mm (0.858″) and extends to 25.2mm (0.992″). The index ring must have high reflectivity, either from silkscreening a white layer, or leaving the disk un-screened in the index ring area. No contrasting features other than a single index mark measuring at least 1.5mm by 3.4mm (0.059″ by 0.134″) may be present within the index ring. The leading edge of the index mark defines the angle. Notice in figure above, the index mark is to the left of the center, setting the index mark angle to a true zero degrees. An Index Mark Angle parameter in the Production Server software tells the system the angle of the index mark. For convenience, Rimage recommends that all index marks be placed at 0 degrees as shown.